A Key to connect the World: IoT Gateway

IoT Gateway – Powering the Industrial Internet of Things: As the Internet of Things expands, businesses find themselves faced with the challenge of integrating many devices and protocols, many with varying power and connectivity requirements. This mix may also include legacy technologies.

IoT Gateways are emerging as an essential component in building a robust IoT and for delivering computational power in edge computing scenarios.

What is an IoT Gateway?

In telecommunications, the primary purpose of a gateway is to provide a bridge between different communication technologies. These technologies can vary in terms of connectivity types, interfaces, or protocols. For example, your Internet Gateway at home connects your Local Area Network (LAN) with your Internet Service Provider (ISP). This gateway links the WAN of the ISP through technologies like PPP or HDLC with your LAN with TCP/IP.

- The IoT Gateway follows the same principle of bridging communications for different technologies. It creates a bridge between the IoT sensors/actuators and the Internet. The IoT gateway aggregates all data, translates sensor’s protocols, and pre-process the data before sending it.

- The IoT devices connect to the IoT Gateway using short-range wireless transmission modes such as Sub-GHz, Bluetooth LE, Zigbee, Z-wave, or long-range like LoRaWAN, Sigfox, LTE, LTE-M, WiFi, and then it links them to the Internet (Public Cloud) through Ethernet LAN or Fiber Optics WAN (HDLC/PPP).

The IoT gateway understands these transmission modes and data (MQTT, CoAP, AMQP, DDS, Websocket) protocols and can translate them to other protocols that the data systems need. [2] (Source: lanner-america)

Functional blocks of the IoT Gateway

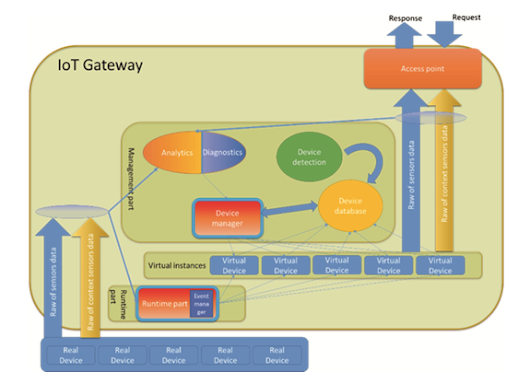

1. Management Functions of the IoT Gateway

Management Functions of the IoT gateway detects, identifies, and networks new devices in real-time. The IoT gateway creates a virtual instance of a device after having discovered it. A definition of the device is needed to create a virtual instance. The definition may contain measurement ranges, device’s location, and power management information, lists of fault states, error states, and error messages. If the definition of the virtual instance is inferred from the physical device, it is uploaded to the device database. The device manager will then create the virtual instance and forward it to the runtime.

The virtual instance communicates with the device in the runtime. The data exchanges are based on events to reduce the communication load. However, the devices in Industry 4.0 should be manageable; at least the device’s status must be settable.

- This solution enables it to connect new devices. The connected devices must provide metadata describing themselves to be correctly recognized. The IoT gateway creates the virtual instances based on the metadata. The virtual instances are frequently refreshed based on the corresponding events. The inactive physical devices are set to an idle state by the device manager. Additional functionality is the management of the running virtual devices. This feature implies another ability to update the physical and virtual instances in real-time.

- The management part provides additional information to the data access point of the IoT gateway and the access point gives it to the higher layers (to MES, for example). The access point also collects information on the configuration of virtual and physical instances from the SCADA layer.

- The diagnostics module enables management of the physical devices, the virtual instances, and the IoT gateway to ensure reliable control of the devices and data transfers from and to the technological layer. The diagnostics module also enables problem identification and invokes events describing the critical or the alarm states.

See more:

2. The runtime part of the IoT Gateway

Runtime part operates with the virtual instances for the physical devices by the management part. Runtime part is responsible for finding new devices and updating the virtual instances. The virtual instances are easily accessible via the unified connection interface of the IoT gateway.

In the case of a fault occurring on the physical device the virtual instance may link itself to another redundant physical device or self-reconfigure. The functionality of another device substitutes the functionality of the faulty device. The runtime part runs an event manager that keeps the physical devices and the virtual instances synchronized.

Management and runtime parts of the IoT gateway [3](Source: researchgate)

The main tasks the IoT gateway

- goog_1177750391Data forwarding – the gateway is responsible for data forwarding from the techno‐ logical layer to the higher layers of the factory architecture.

- Gateway management – the gateway is a key integration element in the entire factory architecture. A fixed and no-manageable gateway will cause fewer problems with adaptivity and implementation.

- Device management – enables runtime configuration of devices, setting the statuses, functionality modes, errors acknowledgements and other.

- Data analysis – the IoT gateway monitors and analyses data in real time using statis‐ tics and artificial intelligence. This module cooperates with the device management to maintain QoS, reliability and fault tolerant operation. The faults are detected and the faulty devices are substituted by the available redundant devices. Data analysis with device management enables self-configuration, adaptive and robust behavior with regard to the technological layer connected to the IoT gateway. The goal is to achieve autonomous management of devices without the need of human intervention aided by M2M communication.

- Diagnostics – the IoT gateway detects errors and faults in the entire technological layer and in the IoT gateway itself.

Kinds of IoT Gateways

Depending on the purpose of use, IOT Gateways are divided into 2 categories: Out-of-box IoT Gateway and Raw IoT Gateways. The following is a table comparing it.

Daviteq

Nhận xét

Đăng nhận xét